|

RIMS AND VALVES |

| Valves |

|

Wheels/Rims |

|

Trelleborg Wheel Systems manufactures its own wheels

and has a wide range of high quality rims.

|

|

Wheel |

|

The rim for a TWIN wheel is a one piece design and rolled

with a profile to allow mounting of the tyre in the best possible way. |

|

|

Rim types |

|

There are two existing main types of rim related to tyre

bead seat angle.

|

|

|

Rim types can be identified by the rim diameter.

|

|

|

Hump rim |

|

Hump is a raised profile on the tyre bead seat, which

holds the tyre firmely in place on its bead seat, even at low pressure. |

|

|

Rim edge reinforcement |

|

TWIN wheels used for forestry and construction machines are often exposed to large mechanical stress and therefore the rim flanges need reinforcements. There are two different reinforcements: box type and round iron type.

|

Box type reinforcement Round iron reinforcement |

|

Valve guards |

|

TWIN rim can be equipped with different types of airvalve

guards:

|

|

|

Rim size |

|

Measurements are always given in inches e.g. 16.00x22.5”

and DW20Ax34”.

|

|

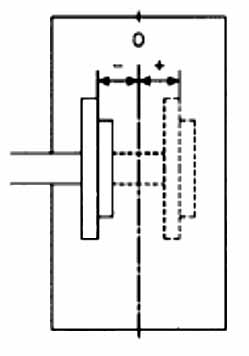

Rim offset |

|

Rim offset states the position for the disc hub contact

surface related to the rim centreline.

|

|

|

Hole pattern/Marking-Disc |

|

To make it possible to fit a wheel on a hub, the disc

must have a hole pattern matched to the wheel bolts and hub configuration. |

|

|

|

|

|

|

Painting |

|

All TWIN wheel rims are painted with a powder coating, giving a very high finish and durability. The wheels can be delivered in following basic colors: silver, white, red, yellow (construction type) ands yellow (John Deere type) as well as other special colors.

|