![]()

|

TECHNICAL NOTES |

|

|

|

Technical Data Symbols |

|

The following symbols are used in the technical data

charts |

|

Dimensions |

|

Size |

States tyre size designation. |

|

LI - SS |

States tyre Load Index and Speed

Symbol. LI is a code for the tyre load capacity at its nominal maximum speed. SS is a code indicating the tyre nominal maximum speed. |

|

PR |

States tyre ply rating and is

a strength code for the tyre carcass. |

|

Type or |

States the tyre tread symbol

or pattern. If it is a tubeless tyre, the tyre is marked with the symbol

TL after the tread symbol. |

|

New tyre |

States tyre diameter and width

in mm, when the tyre is originally mounted with a nominal inflation pressure.

Since some variation occurs between different versions and manufacturing

batches, the tolerance is stated to +/-1.5% for the diameter and +/-2% for

the width. |

|

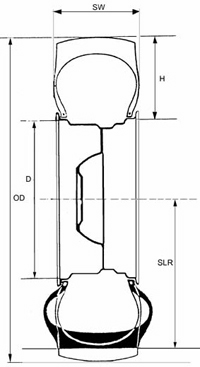

SW |

The Section Width of the unloaded

tyre. If the tyre is fitted on a rim which is narrower (or wider) than that

underlined, the section width is obtained by decreasing (or increasing)

the value shown by 40% of the rim width variation (in millimetres). |

|

OD |

The Overall Diameter of the

unloaded tyre. |

|

R.C. |

Rolling Circumference at reference

load and pressure. Distance covered in one complete revolution of the wheel

on an asphalt road. Value in mm measured according to ISO11795. A tolerance

of +/-2.5% is stated to cover variations between different manufacture batches,

climate elements etc. |

|

SLR |

Static Loaded Radius is the

radius from the wheel centre down to the ground, at reference load and pressure.

The difference between unloaded radius and static loaded radius is called

deflection. This value varies between 15-30% of the tyre section height,

depending on tyre type. A tolerance of +/-2% is stated to cover variations

between different manufacture batches, climate elements etc. |

|

SRI |

The Speed Radius Index states

a theoretical value only to be used for calculation of the max speed of

a vehicle according to EU homologation procedures. |

|

Tyre in service |

States the tyre max. diameter

and width in mm that the tyre may reach during its lifetime. These are the

measurements manufacturers should pay attention to when designing new vehicles

and machinery, to obtain adequate clearance for the wheel. |

|

|

Rim |

| States recommended rim size. Rim width is

expressed in inches e.g. 16.00. A letter symbol in connection with

rim width represents the code for the rim contour. The rim diameter is expressed

in inches. Rim diameters ending with 0.5 (17.5, 22.5 etc.) are 15-degree

rims. Remaining rims are 5-degree (34, 38, 42 etc.). In the table only the rim width is stated. Please check the list of rims included. |

|

Tube |

| States the tube to be used for each size. Example of tube marking: |

|

Agricultural radial tyre: |

38" T 970

|

|

|

Where more than one tube is shown

for the same tyre, pay particular attention to the rim and/or valve type. The type of valve required can be identified from the markings on the tube, using the following codes: |

|

|

|

|

STT brand |

|

|

TWIN brand |

|

|

Speeds |

| The speeds indicated

in the table represent the maximum speed in use for the tyre at the given

loads and pressures. Speed notation in bold types states the nominal speed

for the tyre. nominale del pneumatico. Speed 1 km/h = 0.62 Mph |

|

Free rolling and driving wheel |

|

|

These are

new symbols used for Implement tyres and states freerolling Loadwise, the load capacity is 30% less for driving wheels than for free rolling wheels. |

|

Inflation pressure |

|

The inflation pressures refer to tyres at ambient temperature. The values

given in the tables represent the "reference pressure"

for the load and speed conditions shown. The actual pressure of the tyre

must be established in accordance with the mechanical characteristics

of the vehicle, the additional load from the use of equipment and additional

storage facilities, as well as the load conditions.

|

|

Load capacity |

| The load capacity is the maximum load (expressed

in kg) a tyre is permitted to carry under specified operating conditions. The nominal load is stated in bold type. |

|

|